Air handling units and ventilation

Buildings have always had a need for ventilation in order to improve the air quality inside. Historically, ventilation was dependent on the chimney and a temperature difference between the indoors and the outdoors, later, opening windows was the means to clear the air. In modern times, the building construction has developed and the outdoor air contains more pollutants. The outdoor environment is also more noisy and there are nowadays clear requirements on both energy efficiency and a good indoor climate. Mechanical ventilation has therefore become fundamental to ensure a healthy and comfortable indoor environment.

An air handling unit as the heart of ventilation

An air handling unit (AHU) is perhaps the most essential part of a solution for ventilation, heating and air conditioning (HVAC). It is a professional and complex installation with the purpose of regulating and circulating air in buildings.

The air handler ensures the process of fresh air intake, conditioning and supply of air into an indoor environment, and it also assures the extraction of used stale air from the same indoor space. The process described, air taken into a building and air extracted, is ventilation. Ventilation is critical to preserve a building and avoid issues related to mould, sick building syndrom and the like. It is also necessary to ensure good air quality inside as research has taught us that good air quality is critical for us to concentrate and perform, recuperate and feel good inside.

Get familiar with our range of air handling units

But why ventilate?

We have been through eras of fire stoves for heating and cooking, fuming industries and polluting transportations, energy crisis, air tight buildings and contagions. Over time, it has become evident that we as humans are healthier, more productive and more comfortable in indoor spaces which are ventilated with the aim to ensure good air quality, hence an inside environment which is safe and allow for people to be at their best.

Today, we spend about 90% of our lives indoors, and it is inside various built premises we do our job, learn for life, exercise, enjoy culture and art, visit doctors, recuperate and sleep. A good indoor climate is essential for us to be able to perform and thrive. However, the human being also affects the built environment with its existence and activities, modern ventilation and indoor climate solutions are developed to ensure a good indoor climate both for buildings and for people inside.

Blog: What is IEQ and why is it important?

Learn more about the indoor climate mattersVentilation, and why use a heat exchanger?

When the air handling unit takes on the process of ventilating, it most often uses a heat exchanger to make use of the heat or cold energy in the different air flows. The extract air from the building is normally warmer than the supply air from the outdoors. The heat exchanger then moves the heat energy from the extract air flow to the supply air flow to minimise the need for additional energy to heat the supply air to an adequate temperature.

There are different heat exchangers which differ from each other both in regards to how they are constructed and how they work, a rotary heat exchanger is for instance totally different from a plate or coil heat exchanger. They may be of different materials to make them suitable for different operational conditions or indoor climate requirements, sorption and epoxy treatments are two examples. Both temperature and humidity efficiency are terms to understand in relation to heat exchangers.

Also, read our blog about minimised internal leakage in rotary heat exchangers

Learn more in our guide

Additional units for heating or cooling

Even with a high temperature efficiency, heat exchangers can generally not cover the entire demand for heating or cooling - additional components are usually needed. Providing an HVAC solution with separate heat pumps or chillers is common, but it is also possible to design a solution with integrated cooling and heating in the air handling unit. A coil will then cool or heat the air flowing through the AHU.

Where to place AHUs?

AHU's are normally placed in the basement, on a technical room level or on top of a building, either indoors or outdoors. All affect the building construction, and possibly also the casing of the unit. The basement choice might need separate underground floors, a technical room level competes with rentable floor space and a rooftop placement require the entire construction to be built to carry the weight. The latter alternative may also imply noise and aesthetic restrictions.

Air handling units can be installed either as centralised or decentralised solutions. A centralised solution normally requires a great amount of floor space for technical rooms, and larger ducts are used to serve the entire building. A decentralised solution is spread out on different floors which obviously requires floor space for each unit, but a large closet might do. Further, a decentralised solution demands smaller duct work which can allow for additional space to be used for rent.

How to choose an air handling unit?

There are several parameters which influence on the choice of air handling units but it comes down to projects' specifications. Most often, these build on air quality requirements which are translated into air flow requirements and which trickles down to a set of suitable unit alternatives. However, projects can also face demands in regards to space and placement – think about the previously mentioned decentralised solution, or a renovation project where the building construction might set limitations.

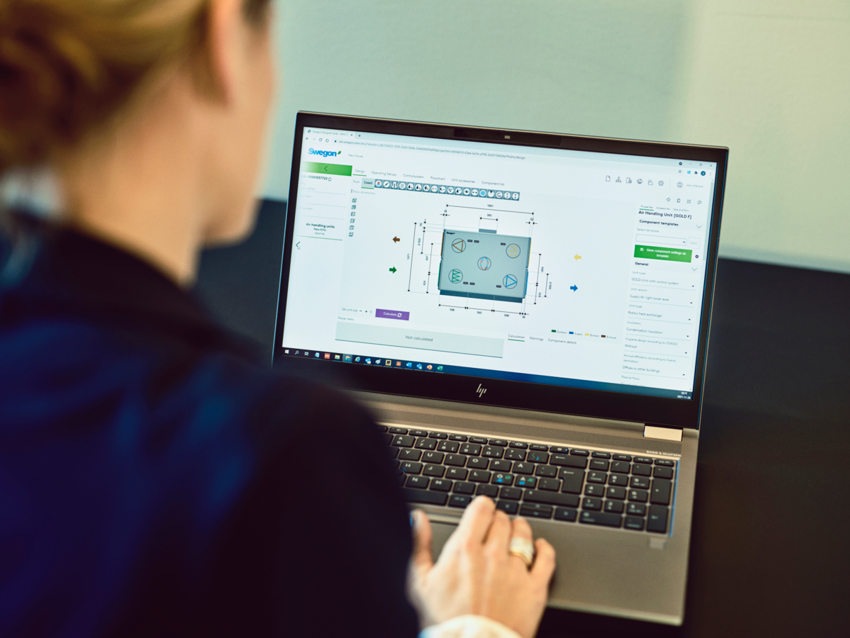

No matter if an air handler is compact or modular, the choice of heat exchanger is an important determinant factor as it influences energy efficiency, and because both indoor and outdoor factors can be completely decisive in this choice. Controls and functionality can impact on the choice of AHU – should the controls be built-in or are there certain functionalities requested for the project? Various sustainability parameters are conclusive nowadays, easy access to EPDs can therefore be highly important. All the above is available in our Swegon software tools, used for designing air handling units according to set requirements for the indoor climate.

Blog: Product selection software in HVAC

See our AHU design selection software

Air handling units, energy efficiency and embodied carbon

Energy efficiency has for long been key in the industry of heating, ventilation and air conditioning (HVAC) as building economics has been critical. Today, energy is also about supply and sustainability as buildings in the Western world have to reduce their energy dependency. Further, we have recoqnised a need and maturity to also address embodied carbon which is why we have evaluated and implemented various circularity processes.

Energy savings cannot compromise comfort

Today, buildings in the Western world stand for about 40% of the total energy consumption. It has to decrease drastically, but it is in that context important to understand that energy consumption, HVAC and indoor climate go together. Energy savings may benefit cost and sustainability, but it is important to ensure a healthy, productive and comfortable indoor climate for tenants to be willing to stay and pay. To opt for an air handling unit with heat recovery is, compared to relying on opening windows, an excellent way to meet all these demands.

A renovation or new-built project are seemingly obvious situations when a solution for ventilation, heating and cooling can be finetuned in regard to energy use. At that point, the design can start from a nearly blank page. However, an installed and operating air handling unit (AHU) can be key in regards to energy savings. Time-schemes, air flows and temperatures have great impact on the energy demand of an HVAC solution, parameters that may be adjusted without major projects or budgets.

Learn more in our energy efficiency guide

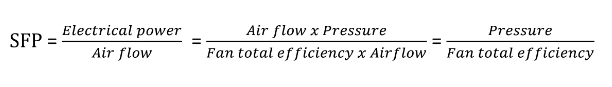

SFP is a measure of efficiency

Specific fan power (SFP) states how much power a fan needs to transport one m3 of air per second. It is stated in the unit kW/(m3/s) which allows us to calculate cost of ventilation by knowing the price of electricity.

SFP has been a relevant factor for many years, and today there is a general trend towards lower SFP values due to the need to reduce the energy consumption as well as CO2 emissions. About 30 years ago, SFP values were around 3 kW/(m3/s) while 1,5 kW/(m3/s), or lower, is the aim in several countries nowadays. When the SFP calculation is examined, it is evident that SFP can only be lowered by reducing the pressure drop and increase the total fan efficiency.

With the above said, SFP is not a great value for solutions designed with variable air flows and/or heat recovery, as both lead to higher pressure drops. However, the energy used by additional heating/cooling units is most certainly reduced when utilising a recovery system in the AHU. A holistic approach is recommended to ensure minimal energy use while not compromising indoor climate.

To our expert's blog post for more information

Air handling units to certify or to build according to standard

It has hopefully been clear that people and planet are intwined when it comes to ventilation and indoor climate. Building certifications and construction standards are means to meet both.

World known building certification standards such as BREEAM, LEED and WELL, are with separate approaches driving developments in energy efficiency and cost-reduction, human health and well-being in relation to buildings and indoor environments. There are also construction standards which specifies how to build to care for the building, the occupant and the planet. Passive House might be the most known of these. Last but not least, air handling units are often also certified by various global and local industry organisations, Eurovent for instance.

Find out more

Embodied carbon

Circularity principles of reduce, reuse and design for disassembly are put in the spotlight as embodied carbon in the construction industry is translated into emissions from manufacturing, transportation, installation, maintenance and disposal of building materials. Exchange of materials, use of less materials, refurbishment of products and reutilisation of existing units are examples of circularity principles in the HVAC industry. Many which are applicable to air handling units.

It has to work as intended, and maintenance is key

The fact that an indoor climate solution is in place is not an insurance of everything working precisely. It can very well be worth to revise a solution to make sure tangible parts are installed and commissioned as intended and that the available functionality in system controls are used to its best ability - make sure everything works as good as it possibly can. Be aware that the use of a building can change over time and that adjustments might be needed to ensure an upkept energy efficiency while still offering a good indoor climate for the people inside.

Even the most well-adjusted air handling unit can cause pointless energy consumption due to filled filters and dusty ducts. Not only will that cause the air handling unit to run more intensively, there is also a significant risk of damaging the AHU’s fan, causing disturbing noise or failing to offer a good indoor climate.

A good maintenance plan is not only an important factor as such, good maintenance is also to do things right. For instance, a falsely fitted filter will cause pressure drops that adversely affect energy consumption.

INSIDE to know more about the AHU

The landscape of digital solutions and artificial intelligence gives opportunities previously not foreseen. Today’s connectivity can allow for an HVAC solution to be monitored and controlled from almost anywhere in the world, and AI can assist in predicting and preparing for expected operational scenarios or projected maintenance needs. This helps to further optimise energy consumption and to significantly prolong the lifespan of as well single HVAC units as entire indoor climate solutions.