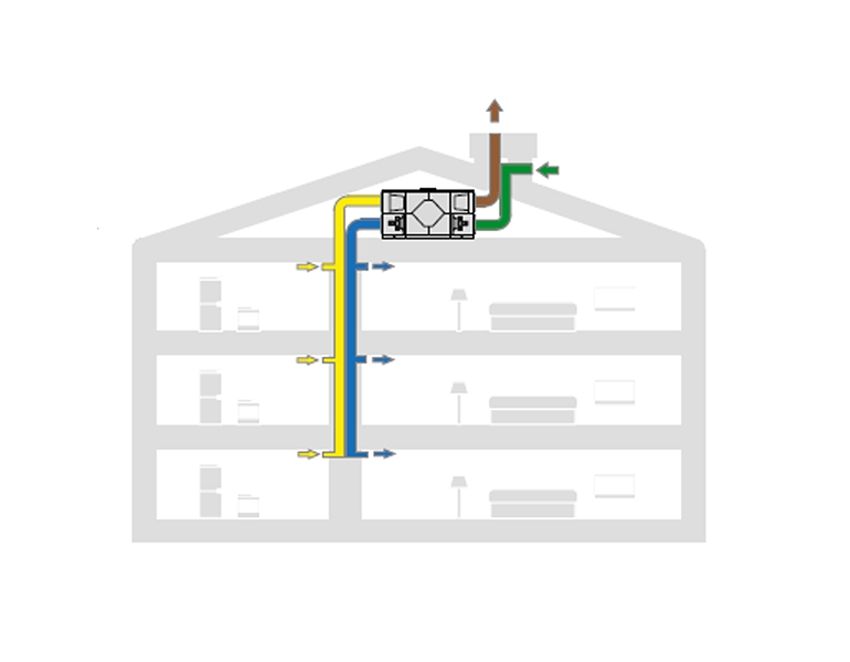

Centralised supply and extract air systems

With heat recovery via heat exchangers, constant air flows.

Unlike a ventilation system based only on treatment of extract air, an air-to-air heat exchange system runs on pre-heated, filtered air. The energy recovery is achieved by means of a heat exchanger, which transfers the energy from the extract air to the supply air. For residential applications, there are basically two types of exchanger options: rotary or counterflow. The counterflow version is the option to go for if you want to eliminate the risk of odour transfer from the extract air to the supply air via the exchanger. In cold climates, the choice tends to fall on a rotary exchanger in order to reduce the defrosting problem.

Efficient heat recovery

An air-to-air heat exchange ventilation system is the usual choice for newbuild installations, owing to its enhanced energy efficiency and indoor climate as compared with a ventilation system based only on extract air. The pre-heated supply air reduces the risk of draughts and of supply air and extract air diffusers clogging up, which can cause noise and flow problems for the entire ventilation system.

The fire protection in an air-to-air heat exchange ventilation system is typically achieved from fans. As a fan in the operational solution, an air handling unit is used with a fire bypass across the unit’s filters and exchangers. Alternatively, mechanical fire protection solutions can be installed in each flat. This requires less space, as the need to fire-insulate the ducts is reduced, since no fire bypass across the unit is needed.

Advantages

- Balanced ventilation

- Reduced risk of draughts and noise

- Several heat exchange options

- Guaranteed indoor climate

- Efficient heat recovery

Disadvantages

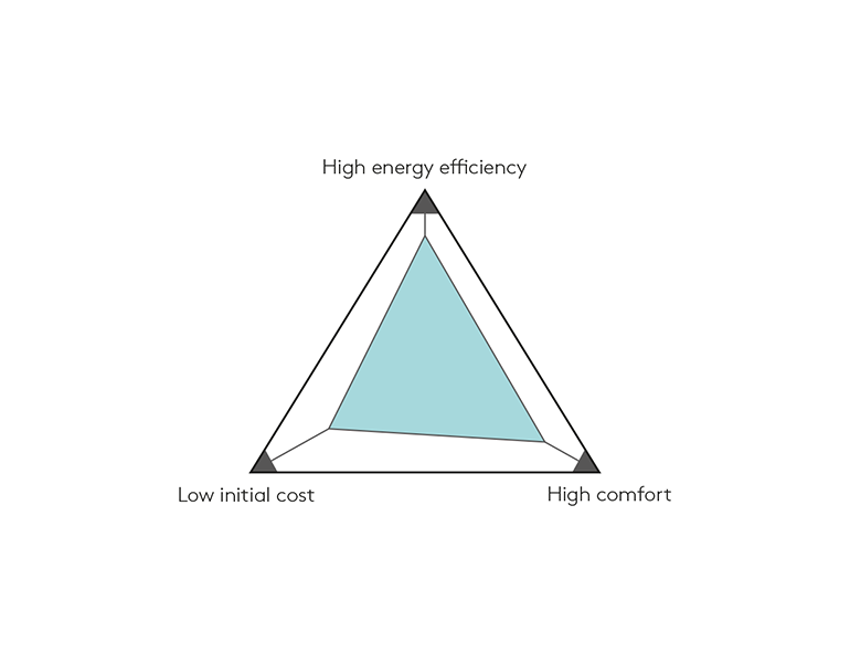

- Costlier to install than an extract-air-only system

- More space-intensive than an extract-air-only system

- Risk of transferral between flats

Learn more: Bacchus in Falkenberg made the most of all the advantages